Menu

wheelchair accessible bbq.

After engaging an industrial designer for the product concept, our client initially looked to China to fabricate and build this product on the understanding that this would be most cost effective. Quotations from local and Chinese fabrications shops were obtained and orders placed with a Chinese fabricator.

On delivery of the prototype, a number of issues were identified which concerned the client.

Britannia had been working with this client for many years, although unable to compete with the Chinese on price for the initial design in hand, we saw the opportunity to redesign the product and panelling around our modern sheet metal equipment. Using this technology and with the sensible removal of labour, we offered to re-scope the project with a view to local manufacture, agreeing on some non-negotiable design outcomes with a view to manufacturing a competitive product in Australia.

Non-negotiable design.

Maintain initial design aesthetics including wheelchair access

Material to be brushed stainless with no visible welds or external fixing screws

To be installed by 2 men in 2 hours with standard tools and no special lift equipment

Solid robust feel

Ability to palletise as flat pack for stacking and shipping

A unit price that would allow sales in a competitive market

design thoughts.

Learning from the prototype, the initial design presented some major issues with structure, visual finish and cost.

Using RHS and cladding to form structure was labour intensive and did not allow the use of CNC cutting and forming equipment which provides labour saving and increased reliability and repeatability in fit form and finish.

Extensive manual welding of Stainless steel required, not only compromised the “look” with heat-affected zones on the outer panels it did not meet the need for clean lines and no visible welds.

Manual welding and finishing of large SS panels were expensive

re:engineered.

- Maintaining the external design lines, Britannia’s engineers looked to a panel concept as a foundation.

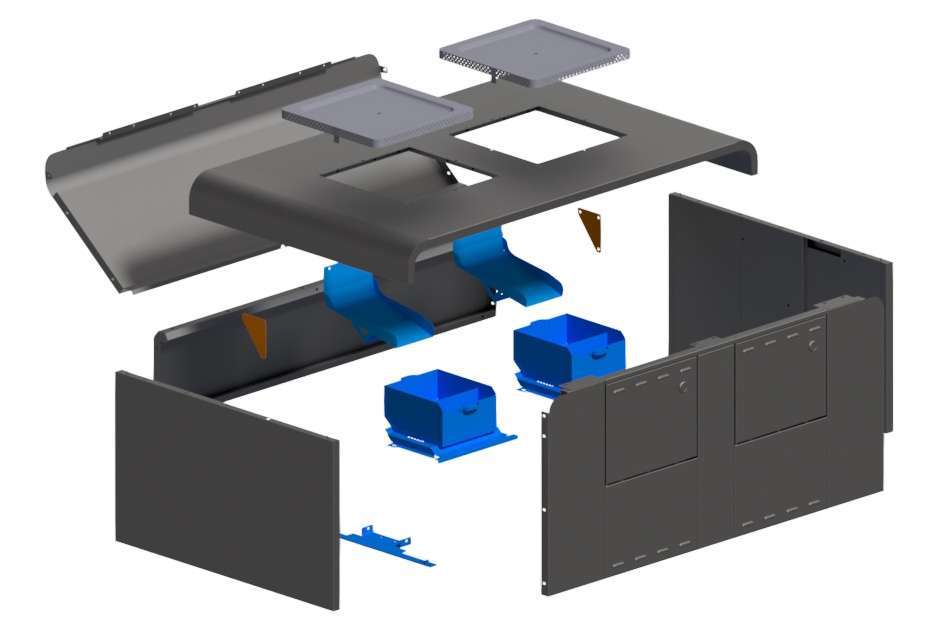

- Interlocking folded panels eliminate the need for an internal tube frame structure. Rethinking the walls as a composite panel structure made up of stainless steel and high density structural foam. Britannia engineers developed an interlocking wall panel that was strong, light and needed little or no welding

- Using Britannia’s Salvagnini panel folder allowed a freedom of design shape including integrating curves.

- Where possible move the joints and connections out of site.

- The design simplified the number of components from 114 to 40

the result.

All non-negotiable design elements achieved and the 2016 Australian Good Design award.

Maintain current wheelchair access

No visible welds or external fixing screws

Solid and robust feel

Ability to palletise as flat pack for stacking and shipping

Installation by two men in 2 hours with standard tools and no special lift equipment

Competitive product manufactured at Britannia